Length: 6m, but customized length availableĬolor: Champagne, rose gold, rose red, coffee gold, black gold, brown, black, red copper, antique copper, brass, titanium, grey, violet, bronze, sapphire, jade green etc. In commercial and hygienic applications, such as restaurants and hospitals, properly finished stainless steel is easier to keep clean. Polishing Compound for Stainless Steel Black solid polish wax Factory. Pool, Grab Bar, Safety Products, Exhaust, Kitchen and Bathroom

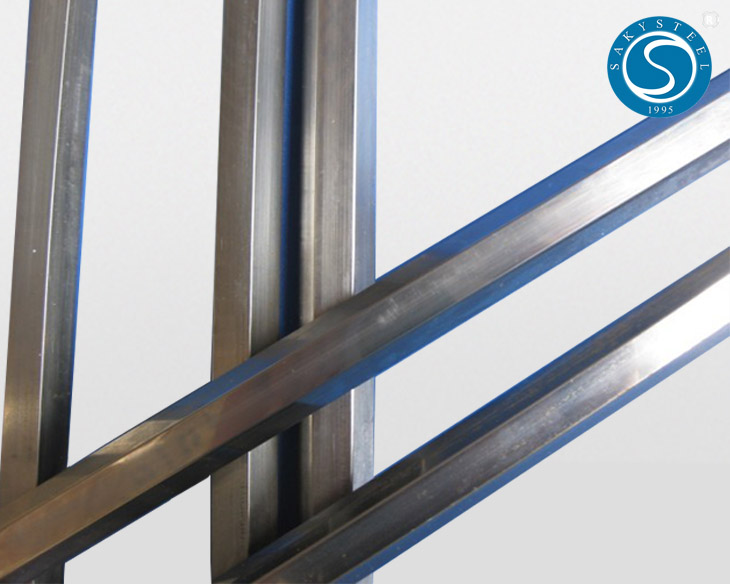

Mill Finish, Brush Polish, 320Grit, 400Grit, 600Grit, Mirror Polish,īuilding material, ornamental tubing, Ship Hardware, Swimming It is found everywhere, from the springs in tanks to the fuel lines carrying vehicle exhausts.Stainless Steel Pipe Fitting / Stainelss Steel Welded pipe at factory priceģ00 Tons per Month or any sizes stock are available for customerĮach for Poly bag, Carton, Bundle, Steel crate, Wooden crate Since WW2, stainless steel has also played a key role in the defense sector. A good quality piece of stainless steel serves as a buffer against the damaging effects of wind and water, maintaining safety and stability. E-TECH Marine Stainless Steel Polish is the perfect compound for polishing and reviving stainless steel surfaces without using a high abrasive content. When it comes to infrastructure, the corrosion resistance of stainless steel helps extend the lifespan of structural and architectural projects. In the medical industry, stainless steel is found in nearly all the equipment that doctors use in their work as well as the many of the small, intricate parts of hospital machinery (such as the EKG or ECG) for monitoring patients. Stainless Steel Round Bar, Stainless Steel Rod Manufacturer, Customer Buy Stainless Steel Threaded Bar from SS Round Bar suppliers in Singapore, Canada. These applications can include food handling/processing (i.e., kitchen sinks, cutlery), medical instruments (i.e., thermostats), hardware, appliances, and structural/architectural uses (i.e., bridges, airport roofs). Unlike ordinary steel, stainless isn’t prone to corrosion, rusting or staining from water exposure – giving it many versatile applications. The most common of these steps include hot rolling, cold rolling, annealing, descaling/ pickling, cutting and finishing. You can have everything from stainless steel tubing and stainless steel pipes to a stainless steel bar and stainless steel sheet.ĭepending on which grade or shape is being produced, a piece of stainless steel may go through some processing steps multiple times before reaching the desired appearance or characteristics. Almost all Earth Materials are used by humans for something. Stainless steel also comes in many different shapes and dimensions. However, common applications of this stainless steel surface finish involve non-decorative purposes. China Factory Provide SUS/DIN/JIS/ISO 316/316L Polishing Stainless Steel Square/Round Bar.

1D stainless steel is sometimes used as the starting point for polished finishes. To all customers who purchase from Jiangsu Sheye Metal, we provide. There are more than 100 grades of stainless steel – most are classified into five groups in the family of stainless steels: The resulting surface is slightly coarse with very low reflectivity and a typical average roughness (Ra) between 47 micrometers. We can polish the surface of stainless channels to mirror finish, brushing finish, or others. The exact composition is strictly measured and assessed throughout the alloying process to ensure the steel demonstrates the required qualities. Other elements can be added to increase corrosion resistance (nickel) and formability (molybdenum).

This type of steel also contains varied amounts of other elements such as carbon, silicon and manganese. Once stainless steel is put into service, it does not need to be treated, coated or painted.īesides resistance to corrosion, stainless steel is known for its: This layer prevents corrosion from occurring on the steel surface the greater the amount of chromium in the steel, the greater the corrosion resistance. The chromium content produces a thin chromium oxide film on the steel’s surface called a passivation layer. Stainless steel is an iron alloy that has a minimum chromium content of 10.5%. Stainless Steel Cleaner Polish is a foamy, white emulsion formula, specifically for use on stainless steel, chrome, and other non-porous washable surfaces.

0 kommentar(er)

0 kommentar(er)